Home »Types of Magnets » AlNiCo Magnets

AlNiCo Magnets

| Types | Features | Applications | |

| Applications | Manufacturing Process | Magnetizing | Graphical Representation |

| Properties |

Alnico is an alloy produced by mixing aluminum, nickel and cobalt with certain addition of other metals like copper, iron and titanium. Capable of producing strong magnetic field, it has an excellent linear temperature characteristics and has wide industrial applications.

Alnico is an alloy produced by mixing aluminum, nickel and cobalt with certain addition of other metals like copper, iron and titanium. Capable of producing strong magnetic field, it has an excellent linear temperature characteristics and has wide industrial applications.

Types

of Alnico Magnets

Types

of Alnico MagnetsOn the basis of manufacturing process and application alnico can be grouped into following types : Features

- Alnico's are the strong magnets which can produce strong magnetic fields.

- Excellent resistance to corrosion

- They have superior thermal stability

- These magnets have some of the highest curie points of any magnetic material ranging around 800oC

- Some type of Alnico's are isotropic

- They have high magnetic flux density

Applications

Applications Alnico magnets have applications in the following areas:

- Electric motors

- Electric guitar pickups

- Sensors

- Loudspeakers

- Cow magnets

- Automotive and electronic sensors

- Actuators

- Hall effect sensors

- Magnetron

- Reed switches

- TWT amplifiers

- Communication

Casting or sintering process is applied for making alnico magnets. The first step involves the pouring of molten metal alloys into moulds. Later it is passed through various heat cycles. The resultant magnets have rough surface which after machining gives a glossy look.

Sintered magnets are produced by compacting fine alnico powder in a press, and then sintering the compacted powder into a solid magnet.

Alnico magnets can only be magnetized only in the field having magnetizing fields of about 3 kOe. Since these magnets have low coercivity they, must be protected from the adverse repelling fields as this could partially demagnetize the magnets.

Magnetizing

After the tolerance magnetizing is effected. As alnico magnets are brittle, theymust be protected from hard blows and handled with care. It should be magnetized in a proper magnetic field and must be prevented from the repelling fields as it is prone to demagnetization.

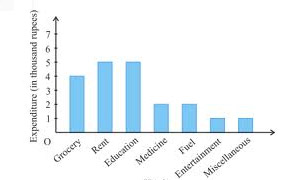

Graphical Representation of Manufacturing Process

| Physical Properties | |

| Curie temperature | 860 |

| Max.Operating Temp. | 525-550 |

| Resistivity | 47-54 |

| Hardness | 520-630 |

| Density g/cm3 | 6.9-7.3 |

| Rev. Recoil Permeability | 1.7-4.7 |

| Saturation Field Strength kOe | 2.7-6.3 |

| Temp.Coefficient of iHc | -0.01-0.03 |