Home » Types of Magnets » Bonded Magnets » Compression Magnets

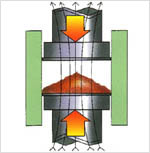

Compression Magnets

Compression bonded magnets are the magnets of maximum strength but comparatively with less physical strength. The tooling costs are relatively low as compared to injection mold. For making compressed magnets neodymium-iron-boron (NdFeB) grades as well as crushed and powdered samarium cobalt (SmCo) are used. As ferrites are ultra small they are not used. For improving adhesion in the magnetic powder, to enhance their corrosion resistance, epoxy binder is used. Due to epoxies, bonded magnets are capable of being used at or above 180°C.

Compression bonded magnets are the magnets of maximum strength but comparatively with less physical strength. The tooling costs are relatively low as compared to injection mold. For making compressed magnets neodymium-iron-boron (NdFeB) grades as well as crushed and powdered samarium cobalt (SmCo) are used. As ferrites are ultra small they are not used. For improving adhesion in the magnetic powder, to enhance their corrosion resistance, epoxy binder is used. Due to epoxies, bonded magnets are capable of being used at or above 180°C. Properties

Following are the properties of compression magnets:

The

higher magnetic density provides the compressed magnets with higher

magnetic strength.

The

higher magnetic density provides the compressed magnets with higher

magnetic strength.

- They are resistant to automotive fluids and industrial solvents.

- The epoxy coat prevents oxidation.

- They have good mechanical strength.

- They can be easily machined.

- Since the materials are isotropic, they can be magnetized in any direction.

- The tools are available in rings, discs and rectangles.

The compression bonded magnets are used in various fields like

- DC motors

- Sensors

- Rotors

- Printers