- Overband Magnetic Separators

- Suspended Plate Magnets

- Magnetic Drum Separators

- Plate Magnets

- Drawer Magnets

- Roller Type Magnetic Separators

- Gravity Feed Magnets

- Grinder Plate Magnets

- Hump Magnet

- Lifting Magnets

- Liquid Line Magnets

- Magnetic Coolant Separators

- Center Flow Magnets

- Magnetic Liquid Traps

- Cartridge Magnetss

- Cross Belt Separators

- Pneumatic In Line Magnets

- Grate Magnets

- Drum Magnets

- Tube Magnets

- Wet Drum Separators

Home » Magnetic

Separators » Drum Magnets

Drum Magnets

| Working | Features | Specifications | Applications |

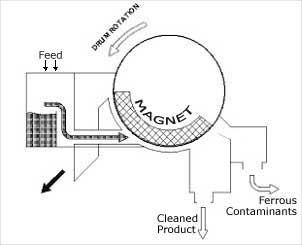

Magnetic drums and drum separators are self-cleaning device that removes ferrous contaminants from a wide range of free-flowing bulk and granular materials in high-volume applications. The stationary magnetic assembly inside the unit's shell captures tramp metal as the material flow into the drum. With contaminants removed, the good product falls freely to a discharge point. As the drum rotates, cleats sweep the ferrous debris through and out of the magnetic field as the drum rotates. The tramp metal is discharged separately thereby creating continuous self-cleaning separation.

Buying Tips

|

Drum magnets work by using a magnetic core to attract ferrous materials to a cylindrical shell. As the shell rotates, it moves ferrous metallic materials out of the magnetic field and into a separate chute or conveyor. There is a adjustable controller from which the materials flow. The controller regulates and directs the product stream onto the drum.

The magnetic assembly at the outer stainless steel drum shell captures the ferrous particles and holds them against the drum surface. As the drum rotates, the tramp metal gets attracted to the drum and travels to the drop point where the magnet assembly ends. The ferrous metal is wiped off the drum by the cleats.

Features

- Drum magnets are powerful magnet assembly combined with high surface holding power

- The magnets have greater magnetic pole area

- They require minimum space and are simple to operate

- They are flexible enough to be applied for various purposes

- Drum magnets have steel support bearings

Specifications

- The materials normally used for housing drum magnets are stainless steel, flanges etc.

- The magnetic materials preferred for drum magnets are either ceramic magnets or rare earth magnets.

- They are available in different sizes and face width.

- Normally the drum magnets have self cleaning design.

- Foundries

- Chemical Industries

- Blast Furnace

- Open Hearth Slag

- Rubber Industries

- Foods Industries

- Grain Industries

- Food Industries

- Tobacco

- Auto Fragmentizing and Processing

Best Practices in Glass Recycling: Ferrous Metals Contaminant Removal