- Magnetic Pulleys

- Magnetic Take-Off Rails

- Cow Magnets

- Circular Vibratory Screens

- Demagnetizer

- Ferrite

- Handle Magnets

- Holding & Retrieving Magnets

- Hopper Magnets

- Magnetic Chuck

- Magnetic Conveyors

- Magnetic Coolant Filters

- Magnetic Hooks

- Magnetic Racks

- Magnetic Rods

- Magnetic Rollers

- Magnetic Sheet Floaters

- Magnetic Slide Conveyors

- Magnetic Stirrer

- Magnetic Sweeper

- Magnetic Tool Holders

- Magnetic Tubes

- Material Handling Magnets

- Prong Magnets

- Round Base Magnets

Home » Magnetic

Products » Hopper Magnets

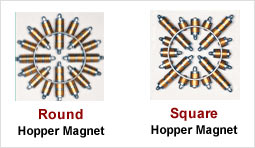

Hopper Magnets

| Features | Applications | Installation |

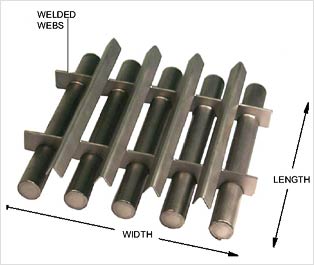

Hopper magnets are basically separators that are engineered for removing ferrous metal and tramp iron from free-flowing materials such as plastics, foods, cosmetics, grains and minerals. Hopper magnets consist of high density permanent magnetic tubes. The tubes are arranged to draw iron particles into the magnetic filed and hold them there as material flows through the grate.

-

Safe to useChoosing Magnet Size

Lots of researches and industrial practices have revealed that the bigger the hopper magnet larger is the area of protection. Magnet bigger in size will allow the material to pass over it even more slowly. This will allow the longer exposure to the hopper magnet's magnetic field of flux. No doubt smaller magnet can be cleaned easily but the materials passed over smaller magnetic area in them is more. - Consist of powerful rare earth magnets which are capable of attracting minutest possible contamination

- The strength of the magnets remain intact. There is no effect on their strength

- They can be cleaned easily after use.

- Available in different shapes, strengths and configurations

- Hopper magnets provide efficient and economical magnetic protection of equipment like mixing machinery, milling, extruding and molding.

The grate magnets like other separators too find their applications in the following industries:

- Food Processing Industry

- Mine and Mineral Industry

- Plastic Industry

- Glass Manufacturing

- Chemical Industry

- Cement Industry etc.

- The size of the hopper magnet should be equal to the size of the magnet as far as possible.

- With respect to hopper feed opening outlet size, the size of the hopper magnet should be bigger by three to four times.

- For effective clearance, the magnet should rest on the inside taper of the feed hopper

- The model should be selected on the basis of the applications.