- Magnetic Pulleys

- Magnetic Take-Off Rails

- Cow Magnets

- Circular Vibratory Screens

- Demagnetizer

- Ferrite

- Handle Magnets

- Holding & Retrieving Magnets

- Hopper Magnets

- Magnetic Chuck

- Magnetic Conveyors

- Magnetic Coolant Filters

- Magnetic Hooks

- Magnetic Racks

- Magnetic Rods

- Magnetic Rollers

- Magnetic Sheet Floaters

- Magnetic Slide Conveyors

- Magnetic Stirrer

- Magnetic Sweeper

- Magnetic Tool Holders

- Magnetic Tubes

- Material Handling Magnets

- Prong Magnets

- Round Base Magnets

Home » Magnetic

Products » Magnetic Sheet Floaters

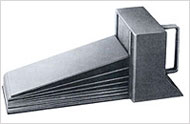

Magnetic Sheet Floaters

| How It Works? | Configuration | Applications |

Magnetic sheet floaters are device used for handling stacked sheets in production jobs. They are cost effective device that performs efficiently thereby giving good productivity. They help boost press and press brake production by eliminating the need to fumble with thin oily sheets. The sheet in the floaters are normally made of stainless steel and are of different sizes, widths and lengths.

There is a steel housing in which powerful permanent magnets are housed. Floaters are positioned by mounting holes. Shifting from one job to other is accomplished by a handle.

Magnetic sheet floaters can be used for:

Magnetic sheet floaters can be used for:

- Heavy and light gauges

- Large and small sheets

- High and low stacks

- Dry and oily sheets

- Irregular and round shapes,

- Polished, painted or printed sheets.

- Protection of polished, painted and furnished surfaces from scratches.